|

|

Product

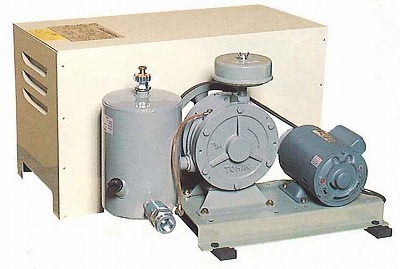

Rotary Vane Blower--FD Type

No. 1 Japanese rotary vane blower -- Four million units shipment

Adapt a new chamber that is tougher for continuous running.

More applications become available.

FD Type was developed based on SD type’s structure, and have a greater

chamber to meet various applications as middle size blower.

Available not only for aeration for on-site wastewater treatment but also

for spray device of a combustion unit.

|

- Unique oiling system that hardly run out lubricating oil in one or two years

continuous operation

- Equipped with a check valve to prevent a trouble caused by back water from a tank

- Built-in Safety-relief valve sounds an alarm to prevent motor burnout, when the motor is overloaded by clogging of pipes or diffuser tube.

- Has an auto-stop function (manual reset) to prevent motor burnout

- Has great durability. Air pressure and flow rate will not change in a long time operation.

- Motor and blower can be separated. Therefore it is flexible for modification to meet the requirements.

- Aeration for on-site wastewater treatment

- Spraying for fuel oil and kerosene oil burners

- Aeration for fish farm

- Agitation in plating tanks or water tanks

- Air curtain

| Model No. |

Dia. of outlet |

Motor power |

F (Hz) |

Blower RPM |

Air flow rate (m3/min) |

Approx. weight (Kg) |

0.01

MPa |

0.02

MPa |

0.03

MPa |

0.04

MPa |

| FD-250s |

3/4" |

300W |

50 |

540 |

0.265 |

0.250 |

0.237 |

0.225 |

47.0 |

| 60 |

540 |

0.265 |

0.250 |

0.237 |

0.225 |

| FD-300 |

3/4" |

400W |

50 |

450 |

0.310 |

0.300 |

0.292 |

0.285 |

53.0 |

| 60 |

450 |

0.310 |

0.300 |

0.292 |

0.285 |

| Parts name and dimensions |

| Advantages of Tohin Rotary Vane Blower |

- Compact, powerful air flowrate and yet silent operating sound

- Very little vibration and easy installation

- Strong against pressure change in a tank

- Smooth outlet by air-chamber unit

- Heavy duty to keep high performance

- Superior cost performance

Tohin rotary vane blower mainly consists of components such as Blower body

(cylinder), Motor, Air chamber, Air filter, Base (with oil tank), and Oil

dropping nozzle. This simple structure contributes very long life and trouble-free

operation.

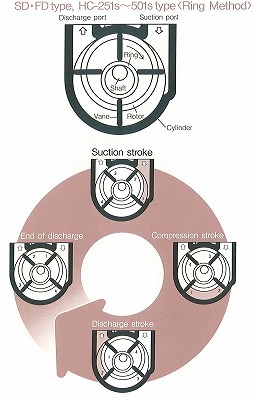

The rotor, which has four pieces of vane moving in-and-out repeatedly,

eccentrically rotates in the cylinder to intake, compress, and discharge

air. This is the basic mechanism of the blower.

While running the machine, lubricating oil keeps circulating and continuously

supplied to the cylinder through the oil dropping joint. The oil works

not only to decrease operation sound and friction heat, but also to keep

high airtightness in the cylinder.

|

|